In which industries is the coal powder briquette machine production line widely used?

The coal powder briquette machine production line is a widely used equipment in the briquette industry. Because of its disadvantages such as a certain amount of native humic acid, low carbon content, and high oxygen content, pulverized coal needs to be compacted to improve its combustion value and the heat generated by combustion. The coal powder briquette machine production line products launched by Lantian can effectively press the coal powder into balls after adding a certain amount of adhesive by stirring, which can effectively reduce the cost of the briquette process. The equipment has the advantages of strong pressure, simple operation, energy saving and environmental protection. In addition to being able to press coal powder, the briquette machine can also press iron powder, coking coal, iron filings, carbon powder, slag, gypsum and other materials. Once launched, it has been widely used in refractory materials, power plants, metallurgy, chemical industry, energy, transportation, heating and other industries.

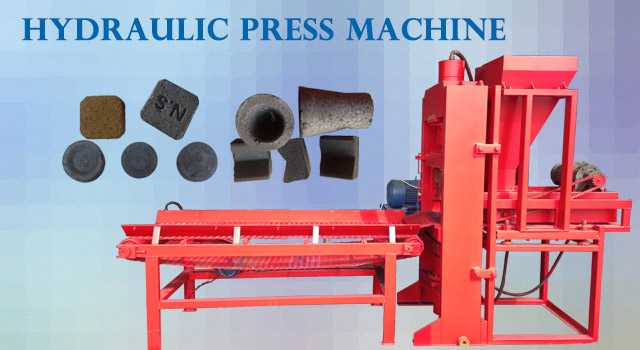

The feed port of the coal powder briquette machine production line is equipped with a mechanical feeding device and a material control device. Regardless of the viscosity of the material, it can ensure continuous and uniform feeding to the rollers of the briquette machine for rolling. The hydraulic station on the frame can flexibly and accurately adjust the rolling strength of the rollers. The combined effect of the material feeding device and the hydraulic station device strongly guarantees the ball forming rate and corresponding ball forming strength of the machine.

1. Adjust the feeding at all times. As mentioned earlier, insufficient feeding will cause the pressed balls to be unstable, so when feeding, it should be determined according to the ball output situation. The best strength is the standard. Too small strength is not good, too large strength is easy to suffocate the machine, and the motor load is too heavy, which is easy to cause damage to the machine or burn the motor.

2. Always monitor whether the conveyor position is normal. When the conveyor position is abnormal, it is necessary to adjust the center bracket. If there is a deviation, it should be corrected in time. If it is biased to the left, the left side should be tightened, and if it is biased to the right, the right side should be tightened until it is not biased.