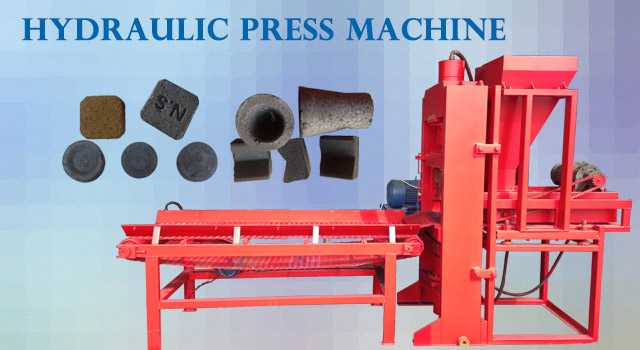

Wood sawdust briquettes machine

1.Description of Wood sawdust briquettes machine

Wood sawdust briquettes machine mainly used wood sawdust to press different shape and size briquettes. This machine include main machine, conveyor,control panel water pump, and hydraulic pressure station.the final sawdust briquettes can used to home cooking and industry area.the diameter for briquettes from10mm-50mm. The height for briquettes from 10-80mm, you can custom the shape and size for the molds.Normal molds:20*20*20mm,25*25*20mm,45*45*60mm,48*48*80mm.Round shape, cylinder shape, hexastyle shape,and other shape you want.

2.Raw material of Wood sawdust briquettes machine

Many raw material can be shaped by this briquettes machine .such as wood , bagasse, rice husk ,corn waste,coconut shell .take wood sawdust as sample:Firstly use crusher crush big size wood into wood powder(sawdust),Then mix sawdust with special raw material,At last use wood sawdust briquettes machine press them, get final products

3.Products of Wood sawdust briquettes machine

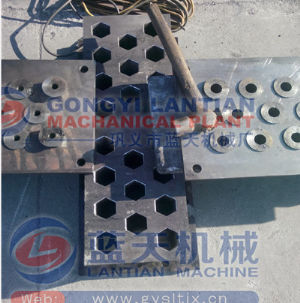

4.Different Molds of Wood sawdust briquettes machine

A-Square mold

B- Hexastyle mold

C-Cylinder mold

F-Honeycomb mold

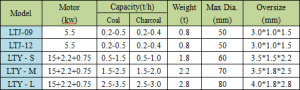

5.Parameters for Wood sawdust briquettes machine

6.Advantages for Wood sawdust briquettes machine

1- Specially designed for the feeder, can be suppressed as sawdust type of light weight, density of pure powder material.

2- Specially designed auxiliary equipment, automatic feeding, automatic film.

3-user-friendly design, the machine easier to clean and maintenance.

4-The transmission system enclosed in the main body below the worm gear box, is completely separate separate components, will not pollute each other, but also to make the drive to be fully lubricated to reduce noise and wear.

5-The special installation structure, so that under the guide rail and the lower pressure roller replacement and maintenance of convenient and quick change.

7.Details of Wood sawdust briquettes machine

A-Semi-finished machine

B-Mold of the machine

C-Finished machine

D-Operation panels

E- One set machine

F- Machine in stock

8.Test and load Wood sawdust briquettes machine

Every week we have customer from different country test machine .they stay in the workshop more than 1 week, check every part of the machine, test machine and learn how to make binder, how to get good products .single machine will packed by wood case, full product machine load by full container, packed by plastic.

9.Swift paper from different customer

After we sighed PI with customer, we will get 30% deposit,then we ready all the machine , after3-7 working days, machine will be finished, customer pay the left 70% money, once we get the bank swift, will contact shipper agent, load machine at once.