Food dryer

1.Description of Food dryer

Heat pump dryer mainly include compressor, control panel ,fine condenser (internal) ,main carton,trolleys and trays .by allowing the refrigerant to complete the evaporation (to absorb the outdoor environment of heat ) → compression → condensation (in the indoor drying room to release heat) → throttling → re-evaporation of the thermal cycle process, which will be external low-temperature environment, the heat transferred to the drying room, the refrigerant in the compressor under the action of the system Internal circulation. It is in the compressor to complete the gaseous phase of the pressurized heating process (the temperature up to 100 ℃), it enters the machine to release high-temperature heat drying room air, while they are cooled and converted into liquid state, when it runs to the outside machine , The liquid quickly absorb heat evaporate again into a gaseous, while the temperature can be reduced to -20 ℃ ~ -30 ℃, then the heat absorb around the air will be an endless stream of heat to the refrigerant.

2.Raw material for drying

Vegetable dryer:Mushroom,Hot pepper and so on

Seafood dryer:Fish Shrimp,Kelp and so on

Tea dryer:Flower tea,Green tea,Black tea and so on

Fruit dryer:Banana,Apple,Grape ,Sweet potato and so on

Dried fruit:Peanut,Walnut,Melon seeds,Pistachio nuts and so on

All the machine control by PLC system, easy operate.

Sample show

3.Different parts for Food dryer

A-Trolleys

B-Trays

C-Inside of the dryer

D-Pieces for dryer

E-Fans

F-Air compressor

G-Control panel

H-Full set

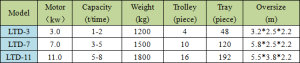

4.Parameters for food Dryer

5.Test for food Dryer

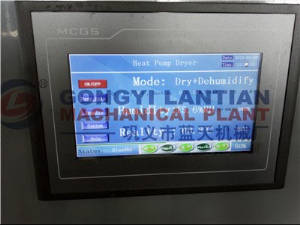

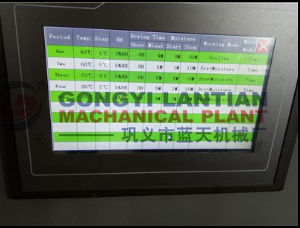

Degree and moisture show

Drying temperature and time show

Drying model

Trolley and trays

Raw material After drying

6.Advantages of Food Dryer

1-Achieve low-temperature air closed circulation drying, dry material of good quality. Through the control device operating conditions, so that the drying chamber of the hot and dry air temperature between 20 ~ 80 ℃, can meet most of the heat-sensitive materials, high-quality drying requirements; drying medium closed cycle, can avoid the external gas exchange May be contaminated with impurities from the material, which is particularly important for food, pharmaceutical or biological products. In addition, when the material sensitive to oxygen in the air (easily oxidized or combustion explosion), can also be used instead of air inert media as a drying medium, to achieve oxygen-free drying.

2, energy efficient. Heat in the heat pump dryer mainly from the recovery of dry room exhaust temperature and humidity contained in the sensible heat and latent heat, the need to enter the energy consumption of heat pump compressor only work, and heat pumps have a small amount of power consumption can be system The heat pump dryer SMER (the amount of moisture in the wet material removed by the unit energy consumed) is usually 1.0 to 4.0 kg / kWh, whereas the SMER of the conventional convection dryer is about 0.2 to 0.6 kg / kWh.

3, temperature and humidity control convenient. When the material into the drying room air temperature and humidity are higher requirements (such as wood, etc.), by adjusting the evaporator, condenser refrigerant evaporation temperature, condensation temperature, to meet the material on the texture, appearance and other aspects of the Claim.

4, recyclable materials in the useful volatile ingredients. Some materials contain volatile components (such as fragrance and other volatile components), the use of heat pump drying, in the drying room, volatile components and moisture together into the air, with volatile components of the air through the evaporator When the refrigerant is cooled, the volatile components are also liquefied and discharged together with the condensed water to collect the condensed water containing the volatile components, and the useful volatile components can be separated by a suitable method.

5, Environment friendly. The drying medium in the heat pump drying device is closed in the circulation, and no dust, volatile matter and odor of the material are discharged into the environment with the dry exhaust gas. The waste heat in the drying chamber is directly recovered by the heat pump to heat the cold and dry air, Thermal pollution of the unit to the environment.

6, can be multi-functional. The heat pump in the heat pump drying device also has a cooling function, in the dry season less, the use of refrigeration functions to achieve a variety of materials, low temperature processing (such as frozen, frozen) or fresh, but also expand the heat pump heating function in the cold Season for the planting (such as greenhouse) or breeding sites.

7, heat pump dryer for a wide range of materials. Dry materials suitable for drying process is mainly resistant to a large range of materials in the temperature between 20 ~ 80 ℃, or although the material can withstand high temperatures, but the use of heat pump drying more energy-efficient or safe materials. (Such as fresh oysters, scallops, etc.), bioactive products (such as oysters, etc.), and other biological products (such as oysters, scallops, etc.) Such as cells, enzymes), tea, paper and so on.

8, Compared with other low-temperature drying equipment (such as microwave drying, vacuum drying, freeze drying), because of the low initial investment and low running cost, the heat pump dryer has obvious economy . Heat pump drying equipment, the cost of the main part of the heat pump and drying chamber part of the drying chamber with the general requirements of the same convection drying room, no special air tightness and pressure requirements.

9, compared with the ordinary drying device (into the drying room air temperature> 40 ℃), the initial investment of heat pump dryer is generally higher than the air electric heating device, gas or coal-fired hot air stove, the initial investment is generally higher than the drying device General drying device, heat pump dryer Drying unit of high energy efficiency, low operating costs, its comprehensive economy is still a certain advantage.

7.Swift paper from different customer

After we sighed PI with customer, we will get 30% deposit,then we ready all the machine , after3-7 working days, machine will be finished, customer pay the left 70% money, once we get the bank swift, will contact shipper agent, load machine at once.

-Payment term: TT, West Union, L/C

-Price term:EXW ,FOB,CIF,DDU,DDP

-Delivery time:3-7Working days after getting deposit