Charcoal extrude machine

1.Description of Charcoal extrude machine

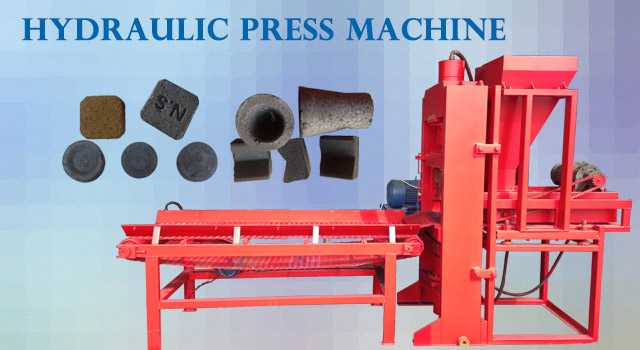

Charcoal extrude machine use different raw material extrude high density and high quality products.hardwood charcoal,coconut shell charcoal,coffee shell charcoal,palm shell charcoal,rice husk shell,peanut shell,corn charcoal, are suitable for the extrude machine.the final products can be custom many shape:Round shape,cylinder shape, hexastyle shape,triangle shape or other shape you want.max diameter 50mm,length adjustable.

2.Details for charcoal extrude machine

Raw material

Products

Molds

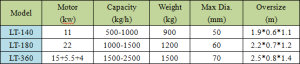

3.Parameters for charcoal extrude machine

4.Different tmodel charcoal extrude machine

140 Model

180Model

360Model

5.Product line for charcoal extrude machine

6.Test for charcoal extrude machine

7.Advantages of charcoal extrude machine

1)-Promise manufacturing quality and reliable, simple structure, easy operation, small size, labor-saving, energy-saving

2)-Automatic control of electric heating device, ensure that the material forming stability, improve work efficiency.

3)- the main parts of the product using a special treatment of wear-resistant materials, it can be suppression of production, durable.

4)-The old-fashioned movement of the three bearings for the four, an increase of machine stability and durability.

5)- Change the old-style oil-type lubrication for oil-immersed lubrication, as long as no shortage of oil can be used for many years.

6)- increase the screw pitch to increase the amount of feed, thereby greatly improving the yield.

7)- improved the structure of the forming tube, reducing the friction of machinery and raw materials, an increase of the density of the mandrel.

8.Load charcoal extrude machine

9.Swift paper from different customer

After we sighed PI with customer, we will get 30% deposit,then we ready all the machine , after3-7 working days, machine will be finished, customer pay the left 70% money, once we get the bank swift, will contact shipper agent, load machine at once.

-Payment term: TT, West Union, L/C

-Price term:EXW ,FOB,CIF,DDU,DDP

-Delivery time:3-7Working days after getting deposit