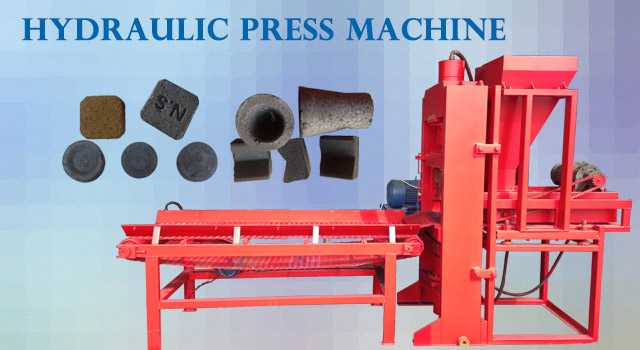

Bamboo charcoal briquettes making machine

1.Description of Bamboo charcoal briquettes making machine

Bamboo charcoal fiber briquettes making machine mainly used to press different raw material into different shape and size briquettes.The principle of Palm kernel shell charcoal briquettes machine is join the turntable on the drum mold, punching charcoal powder into different shape. In the past, charcoal briquettes just used for home cooking,and heating, after several improvements,its also used for BBQ and Shisha ,Popular in Afghanistan,Kuwait, Indonesia, Vietnam,Malaysia, and Arab.

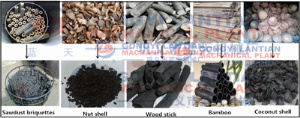

2.Raw material of Bamboo charcoal briquettes making machine

Many raw material can be shaped by coconut charcoal briquettes press machine.such as coal powder, charcoal powder, coconut shell charcoal,rice husk charcoal, wood stick charcoal ,palm shell charcoal, nut shell charcoal, bamboo charcoal,pal, kernel shell charcoal core cob charcoal,peanut charcoal and other biomass waste charcoal. Coal is a kind of solid flammable mineral which is buried in the underground and has undergone complex biochemical and physicochemical changes gradually.but its nonrenewable resources,so we should use carbonized stove to make charcoal from coconut shell,rice husk,palm shell, bamboo and others.No smoking and not worried Shortage of resources.

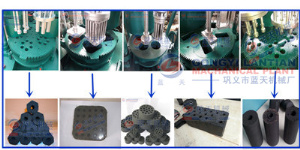

3.Molds and products of Bamboo charcoal briquettes making machine

The mold of briquettes machine can be easily exchanged ,make it meet different markets need.the normal molds are: Square shape, Rod shape,Cylinder shape, hexastyle shape ,Round shape .we accept client’s custom for different molds.normal diameter of the charcoal briquettes are 40mm, 80mm,100mm,110mm,120mm, 220mm,250mm.

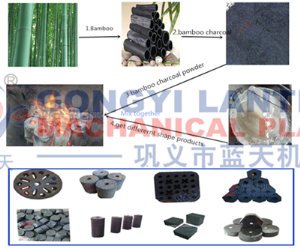

4.Product line for Bamboo charcoal briquettes making machine

Take Bamboo as sample:Firstly use carbonized stove get charcoal from bamboo fiber Secondly use charcoal crusher crush charcoal into charcoal powder, Thirdly ,mix charcoal powder with binder, At last use bamboo charcoal fiber briquettes making machine press the mixed raw material into BBQ . If you want automatic product line, need add conveyor and feeder, save workers and time.Full product line include those machine :Carbonized stove -Crusher-Screw conveyor-Feeder-Conveyor-Binder Mixer-Conveyor-Feeder-Conveyor-briquettes making machine

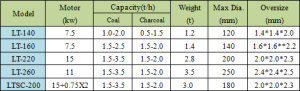

5.Parameters for Bamboo charcoal briquettes making machine

6.Different LT series briquettes making machine in Factory

7.Advantages for Bamboo charcoal briquettes making machine

1.Briquettes height adjustable, suitable for any regional sales and use.

2.Briquettes machine is a first-class transmission of high-pressure briquette machine, adapt to high temperature alpine weather.

3.The installation is fast, no foot bolts stable, ground-based balance of circumstances, then electricity can be used.

4. Machine spindle with steel gears, gears all within the body fuel tank, put an end to direct contact with the ash tip, closed performance, maintenance-free.

5.Machine internal spline shaft, to avoid breaking the key phenomenon, centering high precision, low noise, extended service life.

6.The spindle within the jacket using laser quenching technology to improve the surface hardness and wear resistance, the use of more robust.

8.Details for Bamboo charcoal briquettes making machine

LT series briquettes making machine ,according to more than 30 years manufacturer experience, its become more and more advanced.The machine is equipped with automatic lubrication system, the internal gear transmission, bearing oil pump forced lubrication, effectively extending the service life of the equipment. Electrical use of the advanced phase sequence control system, the motor parts using electromagnetic brake device, reliable equipment to prevent reverse the damage caused. The main drive and toggle parts are equipped with a safety device, more effective to prevent accidental failure can make the device immediately stop running, play a protective effect on the equipment parts.all the parts of machine produced by our workshop,keep its quality.

9.Customer test and load Bamboo charcoal briquettes making machine

Every week we have customer from different country test machine .they stay in the workshop more than 1 week, check every part of the machine, test machine and learn how to make binder, how to get good products .single machine will packed by wood case, full product machine load by full container, packed by plastic.