Coal briquettes machine

1.Description of coal briquettes machine

Coal briquettes machine mainly used to press different raw material into different shape and size briquettes.Its usually also known as briquettes, in the cylindrical cake out of a number of holes. The principle of coal briquettes machine is join the turntable on the drum mold, punching coal powder into Honeycomb. In the past, honeycomb coal briquettes just used for home cooking,and heating, after several improvements,its used for BBQ and Shisha ,Popular in Afghanistan,Kuwait, Indonesia,Vietnam,Malaysia,Arab.

2.Raw material of coal briquettes machine

Many raw material can be shaped by coal briquettes machine.such as coal powder, charcoal powder, coconut shell charcoal,rice husk charcoal, wood stick charcoal ,palm shell charcoal, nut shell charcoal, bamboo charcoal,core cob charcoal,peanut charcoal and other biomass waste charcoal. Coal is a kind of solid flammable mineral which is buried in the underground and has undergone complex biochemical and physicochemical changes gradually.but its nonrenewable resources,so we should use carbonized stove to make charcoal from coconut shell,rice husk,palm shell, bamboo and others.No smoking and not worried Shortage of resources.

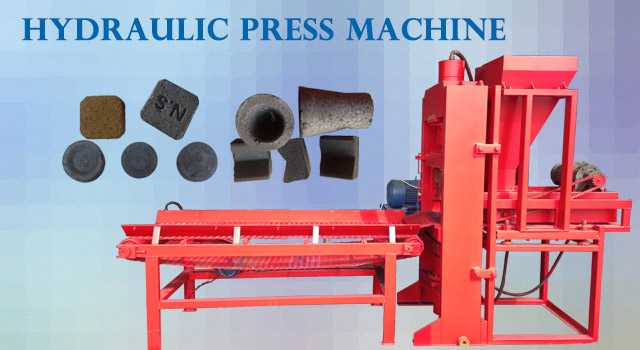

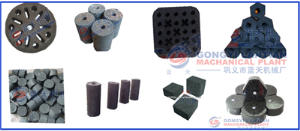

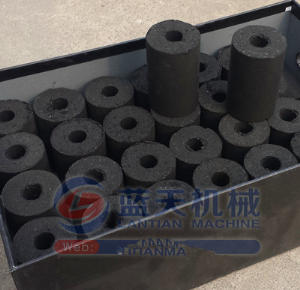

3.Molds and products of coal briquettes machine

The mold of Coal briquettes machine can be easily exchanged ,make it meet different markets need.the normal molds are:Square shape, Rod shape,Cylinder shape, hexastyle shape ,Round shape .we accept client’s custom for different molds.normal diameter of the coal briquettes are 80mm,100mm,110mm,120mm, 220mm,250mm.

4.Product line for coal briquettes machine

Take coal as sample:Firstly use crusher make coal powder from coal, Secondly use mixer mix coal powder with binder, At last use coal briquettes machine press the mixed powder into coal briquettes.if you want automatic product line, need add conveyor and feeder, save workers and time.Full product line include those machine :Crusher-Screw conveyor-Feeder-Conveyor-Binder mixer-Conveyor-Feeder-Conveyor-Coal briquettes machine

Coal powder

BBQ mold

Round shape BBQ

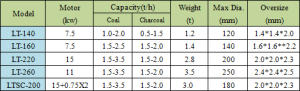

5.Parameters for coal briquettes machine

6.Structure for coal briquettes machine

The machine is simple, divided into the body, turning,feeding,stamping, conveying five parts. Each part of the co-ordination, coordination and smooth operation.

1, the body part: from the table board, base composition, open into the skeleton of the machine body.

2, the transmission part: the motor, pulley, gear, drive shaft and other components. Motor through the pulley gear shaft rotation and through the two gears to the drive shaft, but also through a pair of bevel gears and rotating shaft driven dial, dial dial to the four-hole disk movement.

3, feeding part: by the shaft, hopper, mixer composition, it is by the axial gear toggle mixer, stir the coal and into the mold tube.

4, stamping part of the four main slider, slide beam, punch, punch seat, punch, pressure plate activities, activities at the end of the spring form. When the machine moves by the two gear rotation through the bar to drive the slide beam, punch down, forcing the punch down, move the plate to move the spring compression, the coal pressure forming and the coal into the coal forming the loose, by the spring Compaction activities pressure plate, the coal pressed determined.

5, the transport part of the conveyor frame, pulley, bracket and conveyor belt. Conveyor belt random rotation of the coal sent out of the body, the conveyor frame adjustable screw can adjust the conveyor belt.

7.Customer test and load coal briquettes machine

Every week we have customer from different country test machine .they stay in the workshop more than 1 week, check every part of the machine, test machine and learn how to make binder, how to get good products .single machine will packed by wood case, full product machine load by full container, packed by plastic.

8.Swift paper from different customer

After we sighed PI with customer, we will get 30% deposit,then we ready all the machine , after3-7 working days, machine will be finished, customer pay the left 70% money, once we get the bank swift, will contact shipper agent, load machine at once.