Biomass extrude machine

1.Description of Biomass extrude machine

Biomass extrude machine can extrude biomass waste into briquettes,the raw material are wood sawdust, peanut shells, rice husk corn cobs and other wood shredders.First use crusher crush them into 10mm powder,then use dryer drying those powder, the moisture content less than 12%,then use extrude machine shaped briquettes by high temperature and high pressure. At last use carbonized stove or charcoal kiln carbonized briquettes into charcoal.biomass briquettes can replace fuel wood and coal,good for the development of the society.

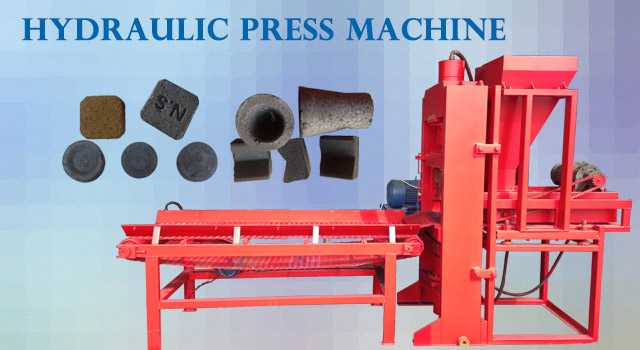

2.Products of Biomass extrude machine

The shape and size of the molds can be custom.normal diameter size for the briquettes are:30mm,45mm,50mm,60mm. The length of the product is adjustable.normal shape are Round shape, Hexagon shape,Square shape,polygon shape.

3. Molds and spare parts for Biomass extrude machine

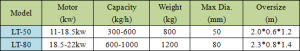

4.Parameters for Biomass extrude machine

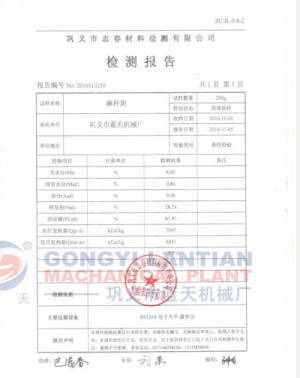

5.Test for biomass extrude machine

Ready raw material

Test machine

Product

Customer check products

After carbonized

Examining report for products

6.Load biomass extrude machine

7.Customer visit

8.Swift paper from different customer

After we sighed PI with customer, we will get 30% deposit,then we ready all the machine , after3-7 working days, machine will be finished, customer pay the left 70% money, once we get the bank swift, will contact shipper agent, load machine at once.

-Payment term: TT, West Union, L/C

-Price term:EXW ,FOB,CIF,DDU,DDP

-Delivery time:3-7Working days after getting deposit